Deeper Dive

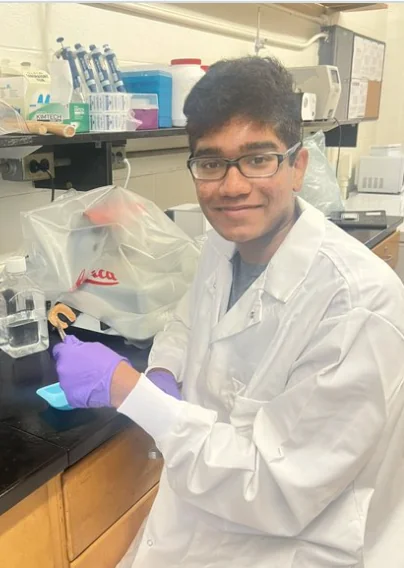

When my mom tore her meniscus, I witnessed as her joint pain eventually progressed to osteoarthritis. As I read more about her condition, I learned that this was not an isolated event–meniscus tears affect upwards of 5 million patients every year. In fact, 65% of all adults above age 65 have meniscus tears, yet no holistic treatment exists. In my project, I 3D printed personalized meniscus implants to regenerate torn tissue. By integrating a polycaprolactone scaffold and gelatin/chondroitin sulfate, I was able to recreate the meniscus’ rheological properties, porosity, and water absorption. Due to these highly optimized factors, my extracellular matrix supported stem cell proliferation and 97% differentiation to healthy chondrocytes.

While designing and executing my experiment, I faced many challenges. Without a formal budget, I learned how to use inexpensive materials available at the lab. For example, I first thought of testing chondroitin sulfate powder in my hydrogel when I remembered my mom taking chondroitin sulfate supplements every day for osteoarthritis. There was no bioprinter at the lab, so I modified a commercial 3D resin-based printer in the lab for PCL scaffold printing. Much of my materials were donated: I emailed various professors and hosted Zoom calls where I presented my work to convey the importance of each item.

My project has many applications in cartilage regeneration and patient care. Meniscus tears are most common among the elderly and athletes, causing immobilization and severe pain. Current industry standard implants are limited by: 1) lack of personalization, 2) non-physiological anatomy, 3) empty negative space, 4) high costs and long waits. These reasons make treatment inaccessible to patients and can even worsen knee conditions. I took steps to address each key issue. 1) I designed my implants through streamlined personalization. MRI scans are the primary diagnostic test for meniscus tears, so I designed my implant based on patients’ MRI scans of torn meniscus tissue. 2) Through iterative design and computational geometry, I recreated essential structures in my polycaprolactone scaffold. 3) I replaced empty space with gelatin/chondroitin sulfate, biomaterials similar to those in native menisci. 4) Due to my cheap materials and streamlined design, I reduced costs by 100 times and cut the waiting time to simply a few minutes. These benefits offer all patients a holistic treatment to regenerate torn tissue rather than removing it.